The Russian enterprise "Everest" began testing of lead shot, shotgun and high-hardness bullets, which will be used by Russian security forces.

At the Everest plant in the Moscow Region, the technology for manufacturing superhard shot, bullets and grapeshot for cartridges used in smooth-bore weapons was designed and adopted.

This development is essentially a response to the presidential appeal to the developers and manufacturers of weapons and ammunition to ensure the powerful technological breakthrough required in the development of our country.

In 2006, the self-loading rifles SSK-18,5 were adopted by the security forces. The rationality of such a decision was based on the fact that this weapon is optimally suited for firing with canister, bullets and gas charges. Smooth-bore weapons are distinguished by high efficiency in conditions of limited spaces - for example, when storming buildings, in street battles, etc.

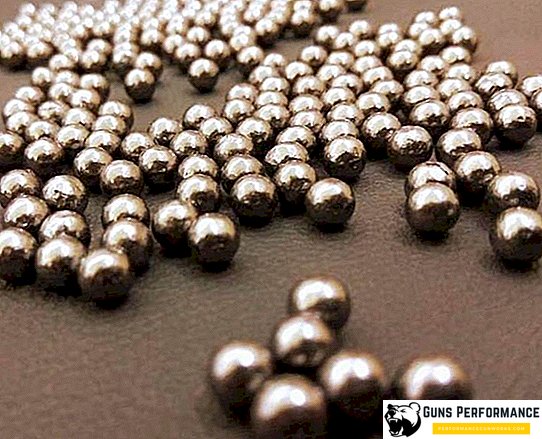

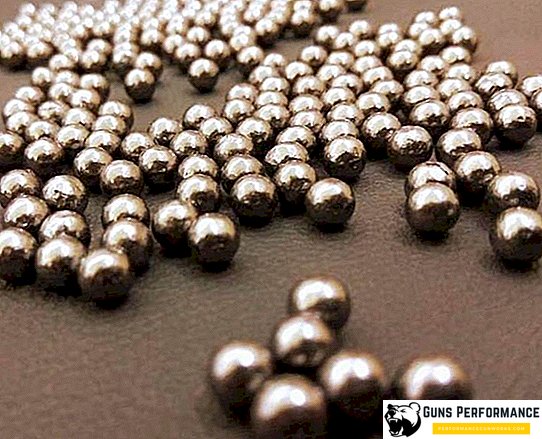

Superhard shot parameters

Nowadays, smooth-bore weapons are widely used by security forces of the United States, France and many other countries. As ammunition often use 12 mm caliber cartridges. This ammunition can be equipped with blinding or bullet charges. A shot from such a gun is guaranteed to hit the target at a short distance.

Bullets with a high mass, have the ability to effectively hit targets that are behind shelters, inside cars. There are also traumatic ammunition that disables the enemy, but at the same time save his life. Due to the fact that the fraction of fast loses its damaging properties, and the probability of rebounding such ammunition tends to zero, the probability of injury of bystanders decreases.

That is what provided the high demand for high-quality ammunition for smooth-bore weapons. These requirements are fully met by the superhard buckshot and bullets produced by the Everest company. Owing to their technical and ballistic parameters, they have higher destructive indicators in comparison with analogues.

Today, the company produces 6 types of stamped gauge from 5.9 to 8.5 mm and 15 types of stamped hard shot.

The key advantage of this unique shot and grapeshot is that they are produced on high-precision foreign equipment using stamping. In comparison with casting, such processing allows to obtain a greater sphericity, and this ensures high accuracy of the fight.

In the manufacture of "slaughter balls" used alloys, which include antimony, providing the hardness of the metal. During manufacture, a layer of granite is applied to the surface of the ball, which provides protection against oxidation. In the manufacturing process constantly produce quality control. Finished products must fully meet the requirements of 25 parameters. Products from the company "Everest" are periodically monitored for compliance with the requirements of GOST in testing laboratories of TsNIITOCHMASH JSC

Studies have shown that the indicator of the hardness of the fraction produced in the company "Everest" is equal to 13 units. The combination of hardness and geometrical correctness of the form guarantee scanty distortion of the form and at the same time ensure defeat of an effective target at a distance of up to 50 m

The company "Everest" over the past two years, became the leader of the arms industry. The products of this company were appreciated by hunters and security officials.