The BTR-60 is an off-road technique developed in the USSR in the late 50s of the last century. The armored personnel carrier was intended to replace the BTR-152, listed in those years in service with motorized rifle subunits. Engineers have improved the permeability of the new model, and also "taught" her to swim.

general information

The 60th model was the first four-axle armored personnel carrier. The development of the line of this technology continues in our years. 16 years (1960-1976) was produced at the Gorky Automobile Plant. Until 1987, the Kurgan Wheel Tractor Plant was engaged in production. Another production point was located in Romania. Local experts collected equipment under the Soviet license (TAV-71).

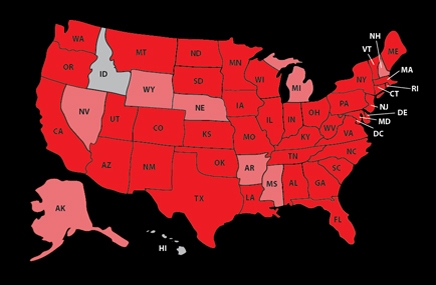

Until the end of the 60s, the BTR-60 was the main vehicle of high traffic in the Soviet army. In the 70-80-ies the number in the army significantly decreased due to the release of the 70th and 80th models. The car went through many military operations, including the Afghan war. Exports were carried out in dozens of countries around the world. Despite the impressive age, the equipment works in the army units of 47 countries (data for 2007).

In our time, the BTR-60 blocking technology is popular. The most common application is the introduction of UAZ vehicles into the bridge construction. In many online stores you can buy a lock BTR-60, both new and old. It’s difficult to talk about the difference in quality, everyone finds for himself certain advantages. The average cost for civilian transport is 8-12 thousand rubles, for the military - up to 19,500.

History of creation

The team of the Gorky Automobile Plant began designing vehicles in the 56th year. The project was led by V. Dedkov. In 1958, engineers prepared the first prototype. The sample was equipped with a carburetor power unit GAZ-40P, which developed up to 90 hp

The first tests showed that power is not enough to ensure the required permeability. Engineers attempted to introduce a YAZ-206B diesel engine (205 hp) into the design, but because of its large mass, they refused this idea. To compensate for the lack of power, they decided to place two 40P engines in the engine compartment. For the stable operation of all bridges, the designers assembled a unique transmission. The final version was prepared in the second half of 59 years.

The BTR-60 outdid many competitors who were created in the 50s on a competitive basis. Simplicity, reliability and low cost - that is why Gorky’s project won the state competition.

The selection committee of Minavtoproma was skeptical about the idea of pairing two engines. The military liked this option: in case of failure of one power unit, the transport could get to the technical center on one (the maximum speed on the highway at the same time is 60 km / h). On November 13, 1959, the Ministry of Defense adopted the equipment.

Design and equipment

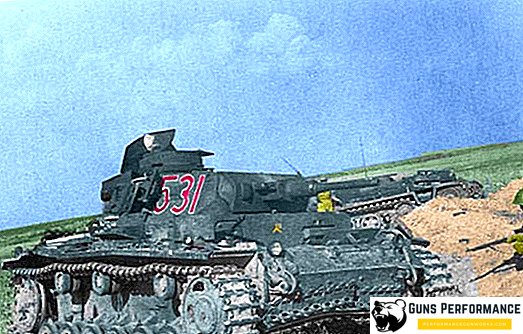

Armored Corps and Tower

Bulletproof protection - weak differentiated. Rolled sheets of homogeneous armor steel underlie the hull (thickness - 5-9 mm). Welding was used to connect them together. For movement on the water body made streamlined. In the design added folding wave deflector.

In the standard version, the body is open. Installation of an awning for protection against a rain is provided. An improved modification of the BTR-60 PB received a fully covered body. Thanks to the numerous rubber seals, the machine has become completely sealed. The filtering installation created increased pressure inside. This did not allow dirty air to penetrate into all branches of the armored personnel carrier.

The front part is highlighted under the control module. It houses two people - the captain and the mechanic. Marines were located in the central part. Aft part was taken under the engine and transmission, as well as other technical units. For comfortable transportation of soldiers in the back there are benches (in different versions a different number). Maximum load on the water - 10 people.

Loading and unloading crew passes through the door (four pieces). On each side there are two doors (located in the upper part). Soldiers have the opportunity to fire from personal weapons from the body of an armored personnel carrier. For this, hatches and hatches are used.

BTR-60 PB was equipped with a truncated conical tower. It was made of the same materials and the same technology as the body. To accommodate weapons and sighting system made three embrasures. Inside the tower is the shooter, directing the shooting. The screw mechanism ensures the rotation of the structure.

Armament

The base version received three machine guns CBMS. The first was in the frontal part of the body, the second and third sides. In modifications of PA and PA1, CBSS was replaced by a similar one in many characteristics. Additional weapons include AK-47, RPG-7 and F-1 grenades.

BTR-60 PB in front of the tower received a symbiosis of KPVT and PKT. For horizontal and vertical guidance screw mechanisms were used. For aiming at the target used periscopic optical sight. KPVT was used to destroy lightly armored or unarmored vehicles (firing range - up to 2 km). PCT was used for neutralization of living enemy objects (firing range - up to 1.5 km).

Observation and communication

Copies of the first years of release were equipped with two front hatches for a review of the terrain. In the conditions of military operations, the B-1 devices (six pieces) took over the functions of the hatches. In the following years, the equipment was supplemented with a TPKU-2B device (the captain used it to inspect the environment). The TVN-2 night-time devices (for the mechanic) and TVN-1 (for the captain) were used in conditions of limited visibility. On subsequent modifications of the PA and PA1, the composition of the survey equipment was preserved.

Visibility in the BTR-60 PB improved. All B-1s were replaced with 9 TNP-B devices. They are located in different parts of the body. Night vision device saved. An upgraded searchlight was added to the device. The troop compartment was equipped with MK-4N periscope viewing instruments. The tower is devoid of viewing devices. There are only sighting mechanisms machine guns.

The first models and modifications for communication were received by radio stations R-113. In PB they improved them, they got the index P-123. In the same version of the BTR-60, the scheme was supplemented with a tank intercom. It was used by the captain, the mechanic and the shooter.

Motor and transmission

Two engines are used for movement at once - the Gorky 40P. They have six cylinders in total, developing up to 180 hp Fastened to a common frame. The first and third axles work at the expense of the right power plant, the second and fourth - at the expense of the left. The captain has the ability to deactivate two bridges. The additional functions of power units include the work of the winch and water jet propulsion. Fuel tanks isolated.

The composition of the transmission:

- Clutch dry type with one disc, complete with hydraulic drive. It comes in a single unit of the engine and gearbox;

- The manual transmission has four stages. Movement through the water is possible due to the operation of the power take-off;

- Razdatka BTR-60 has a step down. Right GAZ-40P ensures the winch drive operation due to the presence of a power take-off mechanism;

- The device of the two main gears includes cam locking differentials BTR-60 of increased friction. This technology is used today in the UAZ as a user tuning;

- Wheel gearboxes (four pieces);

- Cardan shafts, acting as connecting elements of transmission units.

The design of the transmission was developed with an eye to the fact that it was possible to move with one faulty power unit. The design provides a self-assembly BTR-60, which provides the same speed of rotation of the wheels, which increases the cross-country ability of the vehicle. The disadvantage of the BTR-60 samoblok is that the system equalizes the rotational speed even in situations where it is not required.

Hodovka

Wheel formula - 8x8. Four bridges are evenly distributed over the base. Two front wheel pairs are driven. Shed tires withstand a bullet hit. The tire pressure is remote controlled by two compressors. Independent suspension is made on the torsion type. The wheels are attached to two levers, which are connected to the body with hinges. Each upper arm of all axes, except the third, is equipped with two hydraulic shock absorbers. With a complete loss of up to two wheels, the technician retains the ability to move.

Water propulsion

Operation of the BTR-60 provides for overcoming water obstacles, so a water jet propeller was introduced into the device. Implemented in the form of a conduit. Placed under the motor. The conduit is equipped with a four-blade propeller, which is driven by both GAZ-40P. The inlet is blocked by a grille, the outlet is closed by an armored damper.

The waterway is equipped with two rudders, which are used for maneuvering surfacing. Handlebars interlocked with turning wheels. Backward movement is provided by blocking the outlet, while water flows are directed to the side openings. If the water jet breaks in the water, the wheels take the role of accelerators (the maximum speed in this case is 4 km / h).

What can be concluded?

The BTR-60 is a legendary armored personnel carrier that has found demand on all continents. For all the time of serial release from 10 to 25 thousand copies went off the conveyor (there is no exact information with documentary confirmation). On the basis of factory equipment, engineers in different countries created numerous modifications. They are designed to perform different tasks, and are operated to this day.

The technology of self-locking differential is now used not only for military purposes, but also civilian. The 60th model became the basis for future generations.