The laser has long been a convenient tool used in chemistry, biology, medicine, engineering, science, and military affairs.

As laser technology developed, interest in the technical and economic characteristics of lasers grew. The high efficiency of the laser has acquired fundamental importance in connection with research in the field of thermonuclear fusion as a source of cheap and environmentally friendly energy. Thermonuclear fusion occurs in dense plasma, heated to hundreds of millions of degrees. One of the promising ways of plasma heating is the focusing of a high-power laser pulse on a plasma target. It is clear that the energy of thermonuclear fusion should substantially exceed the energy costs of creating a plasma in which thermonuclear reactions will occur. Otherwise, such a process will not give any economic benefits. The search for a constructive solution that will provide a high laser efficiency and acceptable performance characteristics revealed the distinctive features described below.

When creating the first lasers, it was important to show the fundamental possibility of amplifying the light beam in a medium with inverse population of energy levels and the possibility of creating a medium with inverse population. The term "inverse population" means that a pair of energy levels occurs in the energy spectrum of an atom in which the number of electrons in the upper level is greater than in the lower one. In this case, the transmitted radiation pushes electrons from the top level to the bottom and electrons give up their energy in the form of new photons. Inverse population is achieved in different ways: in chemical processes, in a gas discharge, due to powerful irradiation, etc.

The proposed device differs from the known analogues by two features.

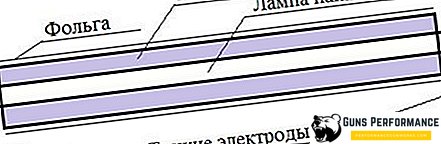

The first feature is that the pump lamp is not located outside the working fluid, but inside it. (Pic 1)

This made it possible to apply a reflective coating directly on the lateral surface of the working fluid (neodymium glass). This feature has increased the efficiency of collecting light from the pump lamp about 4 times.

For comparison in Fig. 2 shows a pumping pattern with four lamps.

The efficiency of collecting light on the working body is reduced in such a scheme due to the fact that the rays in the sector with angle α do not focus on the working body at all, moreover, the rays going at a small angle to the lamp axis do not fall on the working body, moreover, the image of the lamp in the working body area exceeds the size of the working body Recall that only rays from a point source are collected at the opposite focus of the ellipsoid. Finally, multiple reflections with partial scattering from the walls of the lamp, from the mirror and from the surface of the working medium also reduce the efficiency of collecting light.

In the proposed scheme, almost all the rays are locked inside the reflector. As a result of reducing the number of required pumping lamps, the volume and weight of the capacitor bank decreased by 4 times. In addition, the generator itself has become easier and more compact.

The second feature relates to the device resonator. A conventional resonator consists of two parallel mirrors, one of which is translucent and the other opaque. In this device, the opaque mirror is replaced with a corner reflector in the form of a glass prism with an inclined entrance face. The slope of the input face allows this face to be positioned at the Brewster angle (; is the refractive index of the glass) to the laser axis (Fig. 3).

In this case, the laser radiation is polarized and is not reflected from the input face of the prism. The main advantage of using this prism is that the reflected beam is strictly parallel to the incident beam. The resonator always remains tuned. At the same time, a conventional resonator with parallel mirrors requires time-consuming fine tuning (alignment). Reflective mirror coating is easy to damage. The prism has no reflective coating. The ray experiences a total internal reflection.

It is interesting to note the design of the adjustment mechanism. (pic. 4)

The mechanism consists of three panels (highlighted in color), connected by flexible elements (black). The first and second panels are connected at the lower horizontal ends. The second and third panels are connected on the left vertical ends. This design gives two degrees of freedom for small turns of the first panel relative to the third panel around the vertical and horizontal axes. For precision rotation, each pair of panels is connected by a differential screw. Half of the screw has a thread, for example, M4, and the second half of the screw has a thread M5. The pitch of these threads differs by ~ 100 µm. One part of the screw enters a threaded hole in one panel, and the other into a threaded hole in another panel.

Turning the screw head a full turn will change the distance between the panels by just 100 microns. In addition, the flexible elements push the panels to each other and completely eliminate backlash. One of the extreme panels is rigidly fixed on the optical bench, a mirror or prism is fixed on the other extreme panel. The adjustment is carried out comfortably and forever.

These features make the laser particularly convenient in field conditions.