Today the bulletproof vest is an integral part of the serviceman’s outfit. But it was not always so. For a long time, the soldier on the battlefield was protected only by the thin fabric of his uniform or tunic.

A bullet-proof vest is an individual protective equipment designed to protect a person (mainly his torso) from the effects of firearms and cold arms. It is made of various materials, the main feature of which is the ability to withstand the impact of a bullet, shard or blade.

Nowadays, the value of the life of a soldier has increased many times, so the creation of new, more reliable and sophisticated species is being done in many countries of the world. On these developments very serious means are spent.

Bullet-proof vests are different, they are divided into classes: a light bullet-proof vest will protect you from a pistol bullet, a knife and splinters, and heavy army bullet-proof vests can also stop a Kalashnikov assault rifle. A concealed vest can be worn under clothing, which is great for security officers and bodyguards.

How effective are body armor on the battlefield? We can give one example: according to statistics, which led the US Army, the use of body armor by soldiers reduced the number of wounds by 60%.

However, before we talk about new developments, we should say a few words about the history of this personal protective equipment.

A bit of history

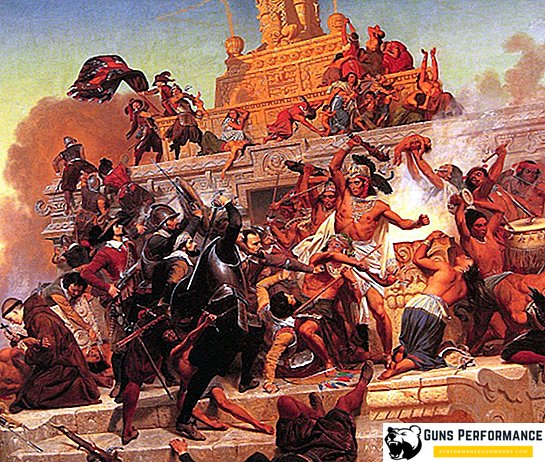

Around the middle of the XVI century, the development of firearms led to the fact that the plate armor could no longer provide sufficient protection for the fighter. In addition, at this time, Europe was moving on to massive recruitment armies, which were quite problematic to provide with high-quality armor. Armor remained on equipment only at cuirassiers and sappers.

After the appearance of machine guns and the improvement of artillery, the troops began to suffer terrible losses. The problem of the protection of infantrymen has escalated. And then the military again remembered the cuirass.

The revival of the cuirass began at the turn of the XIX-XX centuries. In 1905, the Russian Defense Ministry ordered 100 thousand cuirass in France. However, the foreign goods proved to be of poor quality and did not provide a sufficient level of protection for the soldier. There were also domestic developments in this area, and often they were superior to foreign analogues.

Many variants of cuirass were developed during the First World War. Practically all the countries participating in the conflict were engaged in this. Breastplates and assault units were most often equipped with cuirass. The feedback on this remedy was very mixed. On the one hand, the cuirass did protect against bullets, splinters and bayonet strikes, but on the other hand, its protective properties depended on the thickness of the metal. Light armor was practically useless, and too thick - prevented to fight.

During the First World War, the British created something similar to a modern bulletproof vest. He was called the "field shield" Dafield, but this protective ammunition was not purchased by the British army. Those interested could purchase it for their own money, and cost a lot of bodywork. It was made of dense fabric, in four compartments on the chest were placed armor-covers, which well kept fragments and pistol bullets. In addition, the shield was quite comfortable to wear.

Deft businessmen made good money on body shields, very often the family gave all their savings to protect their husband, father or son at the front.

Mention should also be made of the Brewster Body Shield or Brewster's Armor, a protective kit consisting of a helmet and cuirass. He provided good protection against bullets and shrapnel, but at the same time weighed 18 kg.

Development of body armor and cuirass continued in the 30s, and during the next world war, but to create a truly lightweight, comfortable and reliable body armor did not work. Mention may be made of the bulletproof steel breastplate, which was developed for assault brigades in the USSR, as well as special splinterproof vests designed for bomber crews in the UK.

In its modern form, a bulletproof vest appeared in the early 50s, they were invented by the Americans and first used during the Korean War. They calculated that most of the injuries are due to the impact of shell fragments and mines with not too much kinetic energy. To protect against these factors, a body armor was created from several layers of high-strength fabrics - nylon or nylon.

The first mass armor vest M1951 was released in the amount of 31 thousand pieces, it was made of nylon and could be reinforced with aluminum inserts. The weight of the body armor was 3.51 kg. Its creators did not set themselves the task of holding the bullets, however, he defended the fighter well from splinters.

The mass distribution of body armor in the US Army began during the Vietnam War. The standard US Army armor of that time is M-1969 (3.85 kg), made of nylon threads.

At this time, the Americans engaged in the development of personal protective equipment for pilots of airplanes and helicopters.

In the 1970s, the first Barrier Vest for law enforcement officers was created in the USA.

In the USSR, the first bulletproof vest 6B1 was adopted for supply in 1957, but it was never launched into mass production. Expand its mass production planned only in the event of a major war.

After the outbreak of hostilities in Afghanistan, the entire stock of 6B1 was immediately transferred to the military. However, for difficult mountain conditions this body armor was too heavy. It was decided to develop a new remedy that would have less weight. These works were carried out by specialists of the Moscow Research Institute of Steel. In the shortest possible time, they created the first-generation Soviet bulletproof vest 6B2, which passed the entire Afghan war.

The main security element of 6B2 was small titanium plates, stacked in special pockets. The vest reliably protected from shrapnel, but the AK-47 bullet pierced him at a distance of 400-600 meters.

For several years of the Afghan war, several body armor were designed. The main direction of their improvement was to increase the protective characteristics. Dushmans rarely used artillery and mortars, most of the wounds of the Soviet military personnel were caused by small arms.

In 1983, the first Soviet bulletproof bulletproof vest 6B3T appeared, in 1985 - 6B5 “Beehive”, a universal bulletproof vest, which, depending on the configuration, could provide a different level of protection.

In the West, the development of body armor went somewhat differently. The Vietnam War can be called traditional (in contrast to Afghanistan) and the number of fragmentation wounds significantly exceeded the losses from small arms. Therefore, the Americans were in no hurry to develop bulletproof vests. In addition, in the mid-1970s, a new promising material for soft body armor - Kevlar - began to be produced on an industrial scale.

In the early 80s, a new soft Kevlar body armor — the PASGT — was supplied to supply the American army. This body armor remained basic for the American army until 2006. However, after the start of operations in Afghanistan and Iraq, the Americans had the same problem as the Soviet troops in the 80s. For counterguerrilla actions needed a body armor, providing protection against small arms.

The first such body armor was the RBA, adopted by the US Army in the early 90s. Its main protective elements were small ceramic tiles laid in a vest of nylon fabric. The weight of the body armor was 7.3 kg.

In 1999, the American army received an armored vest OTV, protecting it from shrapnel. When installing additional protective panels, this body armor can withstand automatic bullets.

In 2007, MTV body armor jackets with splinter protection were adopted to supply the US Army.

After the collapse of the USSR, work on new types of personal protective equipment was frozen for many years. In Russia, they were returned only in 1999. The Barmitsa program has developed a whole range of body armor of various classes and characteristics.

General device and classification of body armor

For the production of modern body armor used various high-strength materials. These are usually synthetic threads (so-called ballistic fabrics), metals (titanium, steel) or ceramics (aluminum oxide, boron or silicon carbide). If earlier armor vests could be divided into “soft” (fragmentation) and “hard” (to protect against bullets), then at present this is not easy.

Modern body armor usually have a modular structure, which allows you to enhance the protection of certain areas with the help of special armor inserts. Lightweight body armor may not have armor inserts and serve as protection only against knives and bullets of short-barreled weapons. But it can be used as a concealed vest body armor, which is perfect for law enforcement officers, bodyguards, and collectors.

Any body armor should be comfortable and practical in operation, its fabric elements have high durability, correspond to their class of protection (see below) and at the same time have as little weight as possible.

The following areas can be named in which the improvement of body armor is currently taking place:

- Manufacturers began to deviate from the idea of creating a universal body armor that is suitable for any "occasions." Instead, highly specialized protections are created.

- Increase the level of protection and reduce the mass of the product. This is achieved by using more advanced materials and improving the design of body armor.

- Differentiation of protection level for different zones.

- The introduction of body armor protection against non-ballistic factors of damage: fire or electric current.

- The trend to increase protection area. In the latest models of body armor, there is usually protection of the shoulders, neck area and groin. Protection of the sides is almost a mandatory feature of the latest models of body armor.

- In the design of body armor trying to make elements for the placement of weapons, ammunition, medicines and other things necessary for the soldier - such as suhpay.

The main criterion for choosing a body armor is its class of protection. It depends on what kind of bullet or fragment it can withstand. However, this is not so simple. Here are the most common types of body armor protection classification:

- GOST R 50744-95 / 1999. This standard of body armor was adopted by Gosstandart of Russia in 1999.

- GOST R 50744-95 / 2014. Russian standard, adopted by Gosstandart of Russia in 2014.

- CEN is a pan-European standard.

- DIN - the standard of protection of body armor of the German police.

- NIJ is the standard for body armor of the American National Institute of Justice.

Now let's look at several protection classes of body armor in accordance with different standards.

GOST R 50744-95 / 2014 (Russia):

- 1 class. Must protect from a Stechkin pistol (APS) 9x18 mm with a steel core (Pst). Bullet speed 345 m / s, a distance of 5 meters.

- 2 class. Pistol "Vector" (CP-1), cartridge 9x21 mm, lead bullet at a speed of 400 m / s, a distance of 5 meters.

- 3 class. The bullet-proof vest of this class must protect against the bullet of the Yarygin pistol of 9x19 mm with the steel heat-strengthened core. Bullet speed 455 m / s, a distance of 5 meters.

- 4th grade. It should provide protection against an AK-74 shot, a cartridge of 5.45x39 mm, a bullet with a steel heat-strengthened core, a bullet speed of 895 m / s, a distance of 10 meters. And also from a shot from AKM, a cartridge of 7.62x39 mm, a bullet with a steel heat strengthened core, a speed of 720 m / s, a distance of 10 meters.

- Grade 5 SVD rifle, cartridge 7.62x54 mm, bullet with steel heat-strengthened core, speed 830 m / s, distance 10 m.

- 6th grade. Body armor of this class must withstand a shot of an OSV-96 or B-94 12.7 mm rifle. Cartridge 12.7x108 mm, bullet with steel thermo strengthened core. The speed of 830 m / s, a distance of 50 meters.

Protection classes for body armor from the National Institute of Justice (NIJ):

| Class | Subclass | Caliber | Type of cartridge | Mass (g) | Max bullet speed (m / s) |

| I | 1 2 | special 38 22 | RN / lead bullet LRHV / lead. bullet | 10.20 2.60 | 259 320 |

| II-A | 1 2 | .357 Magnum 9 mm | Jsp FMJ | 10.20 8.00 | 381 332 |

| II | 1 2 | .357 Magnum 9 mm | Jsp FMJ | 10.20 8.00 | 425 358 |

| III-A | 1 2 | .44 Magnum 9 mm | SWC / Lead bullet FMJ | 15.55 8.00 | 426 426 |

| III | - | 7.62 × 51 mm NATO | FMJ | 9.70 | 838 |

| IV | - | .30-06 Springfield | AP | 10.80 | 869 |

What's next?

What are the body armor in the foreseeable future? It is difficult to give an exact answer to this question. There are several interesting developments that may become a reality in the coming years.

Body armor

Similar studies are engaged in the Americans. It has long been known that silk cobwebs are one of the most durable compounds in nature. It is slightly inferior to Kevlar, but much more elastic than the latter. The US military has allocated 100 thousand dollars to continue research, and if they are successful, the scientists will allocate another million dollars.

Liquid body armor

Another interesting direction in the field of creating perfect armor is the development of body armor based on a special gel, which, upon impact, goes into a solid state. Thus he absorbs the energy of a bullet or shard.

Similar work is being done in several countries at once, and the developers promise to demonstrate practical results in the near future. In physics, such gels are called "non-Newtonian fluids."

Experiments have shown that such a "gel" body armor is not inferior in its protective properties to thirty layers of kevlar fabric.